Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

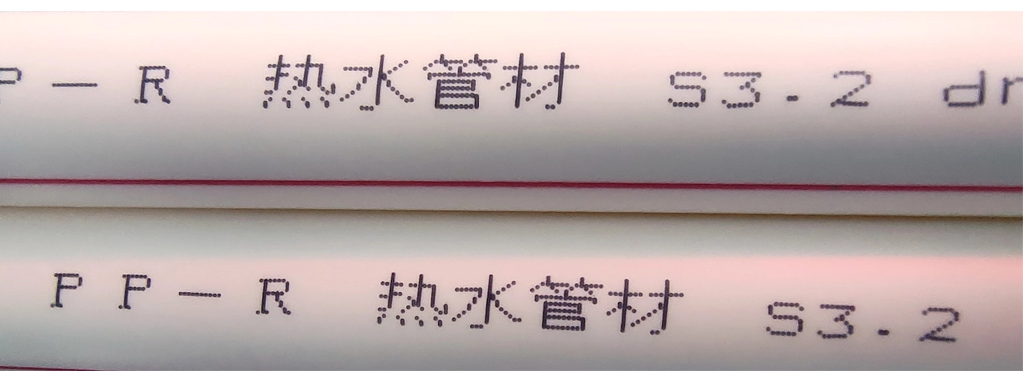

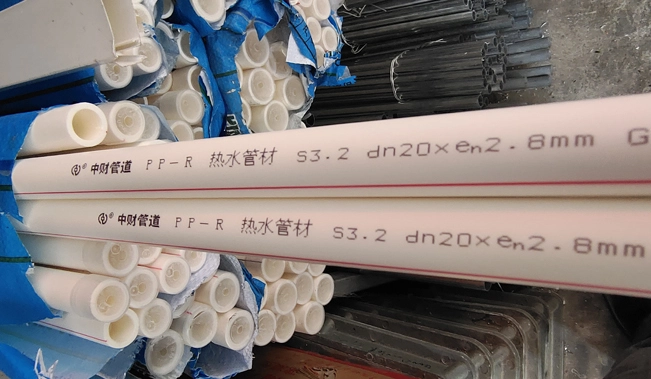

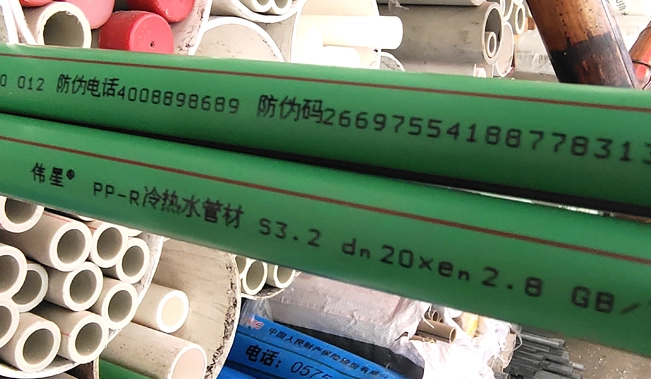

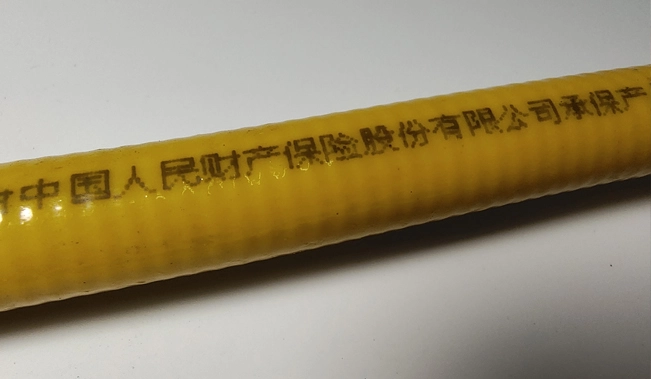

Today, inkjet printing technology has been widely used in various products in the pipe industry, such as water supply and drainage pipeline trunking, aluminum plastic pipes, composite pipes, rubber hoses, etc. The marking is accurate, clear and easy to read, and the automatic meter counting function meets the requirements of pipe industry marking.

1. Suitable for operation in high temperature and high heat production environment.

2. The inkjet printing is clear, stable, clean, wear-resistant, and mobile-resistant, without defects or dirt.

3. The printed characters are as small as 0.8 mm, which meets the marking requirements of tiny pipes.

4. Various complex graphics or factory logos and standard certifications such as TUV, UL, CE, etc. can be printed. • It can be connected to other electronic equipment, such as eddy current flaw detectors, and can also be linked to the factory's automated management system.

5. Different colors or opaque inks can be printed on the surface of products or components of different materials.

6. Automatic meter counting function, continuous and instant printing information, does not affect the continuous operation of the entire production process.

1. Water supply and drainage pipes of various calibers.

2. Wire ducts of various specifications.

3. Aluminum-plastic pipes and composite pipes of various specifications.

4. Flexible hoses of various specifications made of rubber, plastic, metal and other materials.

1. Product identification The pipe industry has many products with different specifications.

2. It is difficult to identify the brand or trademark from the appearance of the product.

3. By printing clear and stable product specifications and factory names and logos,

4. It can quickly identify genuine products, protect economic interests, and combat counterfeit products.

5. In addition, the non-wearability of the mark can ensure the durability of transportation, handling and storage.

6. Laws and regulations Usually, industries and laws and regulations stipulate that manufacturers must indicate the origin, specifications, manufacturers and other product information on the packaging or outer box of the product. The use of inkjet technology can meet these regulations and protect customers' commercial behavior in market sales, product exports, etc.

7. Reduce costs Effectively reduce costs, reduce downtime in the production process, and reduce the intensity of personnel work.

8. Anti-counterfeiting and cross-regional sales Print special marks (graphics, fonts, codes) on products or outer packaging or use special functions such as invisible ink to prevent the circulation of counterfeit and fake products. In the pipe industry, spraying technology has become one of the most effective anti-counterfeiting means. In addition, customer management can be carried out by printing different numbers and graphics to prevent cross-regional sales and cross-border goods.

9. Logistics needs Printing barcodes on product packaging can speed up product classification and circulation, make the management between production lines and warehouses more reasonable and scientific, and strengthen the monitoring of raw materials and effective management of inventory.

10. Product added value For users, clear and accurate identification is a standard way to identify the brand, and it is also a sign of confidence for long-term safe use. For manufacturers, using coding technology can improve the brand's market image and unified logo management, establish a good recognition image and beautify the product appearance.

1. Multiple color options, white, blue, green, red, etc.

2. Different functional configurations, such as the clever combination of white ink machine and opaque ink.

3. Good resistance to cleaning with chemicals such as migration alcohol.

4. Anti-ultraviolet radiation.

Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

+8615158686279

allie@langdetech.com