Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

When choosing a printer, dairy companies need to consider multiple factors to ensure that the printer can meet production needs, ensure coding quality and production efficiency. The following are some key considerations:

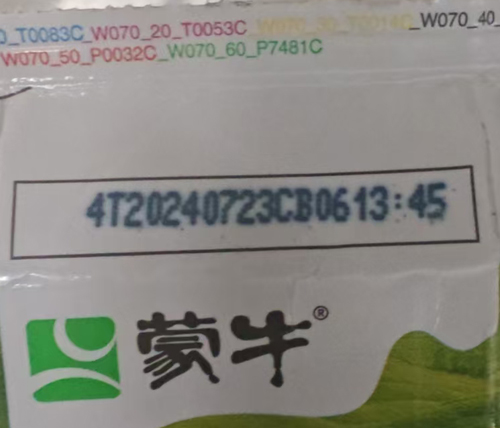

Packaging materials: Dairy products are packaged in a variety of materials, such as cartons, plastic bottles, glass bottles, etc. Different packaging materials have different requirements for the adhesion and durability of the inkjet code. For example, when coding on plastic bottles, the inkjet printer's ink needs to be well combined with the plastic material and not easy to fall off; while when coding on cartons, the permeability of the ink needs to be considered to avoid smudging.

Packaging shape and size: For irregularly shaped or small-sized packaging, such as yogurt cups, cheese sticks, etc., the printer needs to have a flexible coding angle and precise positioning function, and can adapt to different shapes and sizes of packaging surfaces for coding.

Cleaning requirements: The dairy production workshop needs to maintain a high degree of cleanliness and hygiene, and the printer should be easy to clean to avoid ink leakage or residues that pollute the production environment. For example, the LD910 inkjet printer uses a fully enclosed ink path system, which reduces the risk of ink overflow and is more suitable for use in environments with high hygiene requirements.

Temperature and humidity: The temperature and humidity of the production environment will affect the performance of the inkjet printer and the drying speed of the ink. In a high temperature and high humidity environment, the ink may dry slowly, causing the inkjet code to be easily erased; in a low temperature environment, the ink may solidify and other problems. Therefore, it is necessary to choose an inkjet printer that can adapt to changes in temperature and humidity in the production environment.

In general, Langde's coding technology can meet the needs of product characteristics and production environment in the dairy industry, helping enterprises to complete production tasks with high quality.

Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

+8615158686279

allie@langdetech.com