Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

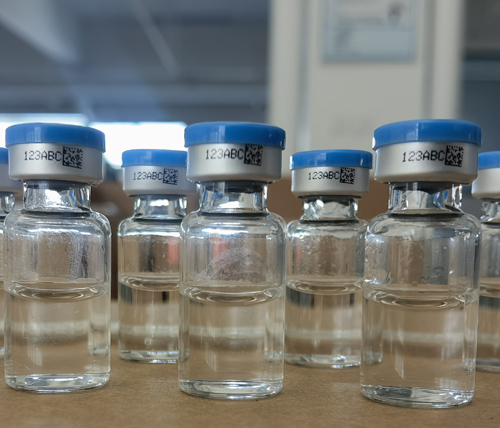

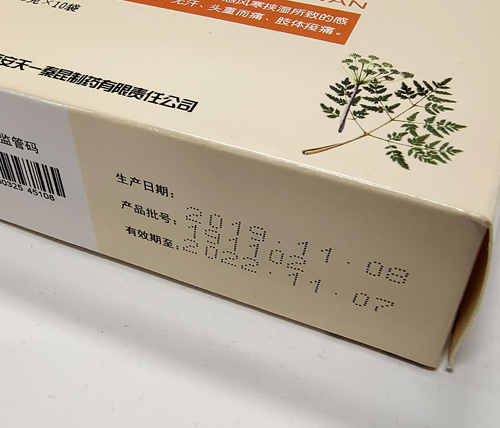

Inkjet coding technology is widely used in the pharmaceutical industry. Throughout the pharmaceutical industry, packaging is also diversified, including cartons, aluminum foil packaging, glass bottles, capsules, films, etc. No matter what the material is, our company can provide marking solutions that meet your standards and provide you with solutions for product anti-counterfeiting, market management, and flow tracking.

The pharmaceutical industry is now fully implementing GMP certification and has strict standards for the application of various pharmaceutical equipment. The inkjet coding equipment provided by our company has three-line printing capabilities and a stainless steel body structure with an IP55 protection level, which can meet the requirements of high-speed and clean packaging lines, huge daily output (up to 10,000 pieces per hour or more), rugged packaging appearance, high-definition and high-adhesion inkjet printing of medical devices, and a series of industry application requirements such as body equipment with different industrial protection levels in the production environment.

Inkjet printer is a non-contact printing technology. Whether it is on small tablets or capsules or on aluminum tin plates or stainless steel surgical instruments, whether it is soft plastic film packaging or carton packaging, whether it is a single product or a whole box of pharmaceutical packaging, our company's inkjet coding solution can meet the changing product marking requirements of different materials in the pharmaceutical industry.

The non-contact inkjet printing function using innovative technology can print in forward, reverse, or upside down directions.

Equipped with a movable print head and side printing, it is suitable for printing outer packaging of aluminum thin or plastic drugs.

Print various expiration dates, production batch numbers and other information, suitable for printing on small medicine bottles and drop packages, in compliance with the provisions of the Medical Law.

Suitable for good operation in harsh working environments.

Pattern editing function designed by independent innovation.

The printing font height is 0.8MM to 15MM, and various variable information can be printed at high speed from 1 to 4 lines.

The printing effect is good, clear and easy to identify in a small area.

Fully automatic clear nozzle for easy operation and maintenance.

Flexible and convenient to move, suitable for printing on cartons, woven bags or plastic films.

It can print up to 6 lines of information, continuous printing, and has complete functions.

Safe edible ink that can be printed directly on medicines.

Quick-drying ink combined with high-speed production.

Develop ultraviolet visible anti-counterfeiting ink to protect your legitimate rights and interests.

Patented glass ink is suitable for all glass containers.

Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

+8615158686279

allie@langdetech.com