Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

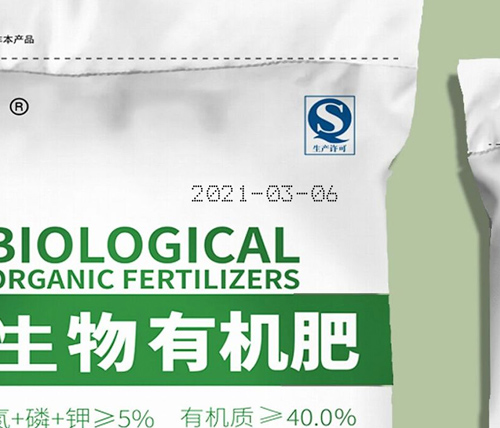

In fertilizer plants, the production environment is complex, not only accompanied by high-salinity air, but also multiple interference factors such as dust and humidity changes. These special conditions are a huge test for the performance of inkjet printers, which are directly related to production efficiency and product quality. Once the inkjet printer fails, it will cause blurred inkjet codes and information errors, affecting the recognition and traceability of the product; it will cause the production line to stop, delay production progress, and increase production costs.

Some brands of inkjet printers did not fully consider the special environment of fertilizer plants during design, and the three-proof treatment was only superficial, with insufficient protection performance. Under long-term erosion in a high-salinity environment, the internal circuits are prone to short circuits and corrosion, and key components such as nozzles and ink circuit systems are also easily damaged. This not only leads to frequent failures of the inkjet printer, such as nozzle blockage and unstable ink lines, which greatly reduces the effect of inkjet printing, but also requires a lot of time and manpower to repair each failure, and the maintenance cost remains high. According to statistics, the average monthly maintenance of these brands of inkjet printers can reach 3-5 times. The cost of each maintenance includes parts replacement, labor costs, etc., which totals more than thousands of yuan. At the same time, it will cause several hours of downtime losses, seriously affecting the production rhythm.

The goal of Langde inkjet printers has been to adapt to complex environments since its development. The three-proof treatment uses nano-protective coating technology to wrap the internal circuit boards and key electronic components to isolate salt, dust and moisture. The parts are strictly screened for high strength and corrosion resistance to ensure stable operation of the equipment in harsh environments. In addition, it is equipped with an intelligent fault diagnosis system to monitor the operating status in real time, immediately warn when problems are found, and provide troubleshooting guides. Technicians can quickly complete maintenance by following the prompts. These advantages have reduced the failure rate of Langde inkjet printers by more than 70% compared to other brands, halved maintenance costs, and significantly shortened downtime, providing a strong guarantee for the continued efficient production of fertilizer plants.

Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

+8615158686279

allie@langdetech.com