Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

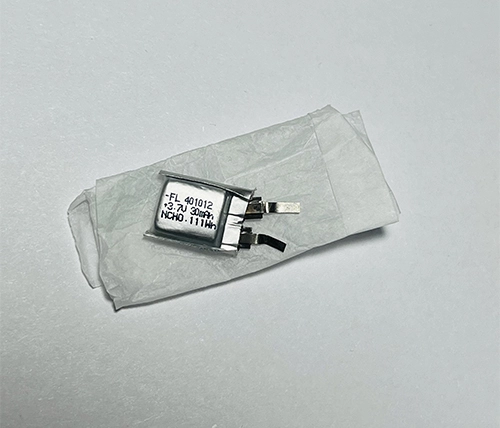

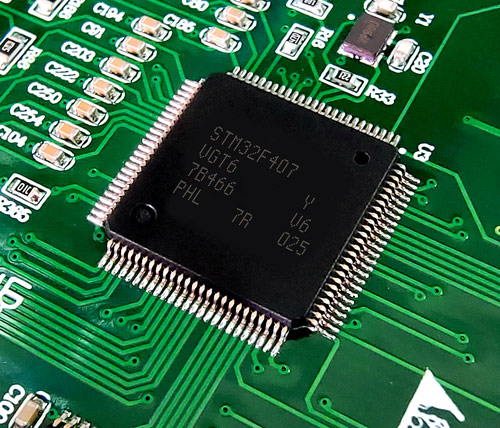

In the electronics industry, many components and circuit boards require marking and coding, typically including part numbers, production dates, and storage dates. Currently, most manufacturers use screen printing or labeling methods, while some opt for coding machines and inkjet printers.

Inkjet printers utilize non-contact coding technology, meeting the diverse marking needs of the electronics industry. Whether for tiny resistors, capacitors, connectors, or larger components like switches, inkjet printers can handle them with ease. They can print Chinese characters, English text, numbers, barcodes, graphics, and other product information.

Suitable for clean, quiet production environments, delivering clear, stable, and clean prints that meet the demands of hygienic production settings.

Capable of printing characters as small as 0.8mm, meeting the fine marking requirements of tiny components.

Able to print complex graphics, logos, and standard certifications such as TUV, UL, and CE.

Prints are resistant to solvents like alcohol, ensuring compliance with industry standards.

Can be integrated with other electronic devices (e.g., weighing scales, PLCs) and factory automation management systems.

Supports inks of different colors for use on various material surfaces.

Request Demo

Please fill the form to let us know your need. We will get in touch with you ASAP.

+8615158686279

allie@langdetech.com